Membrane structures, tensile membrane

|

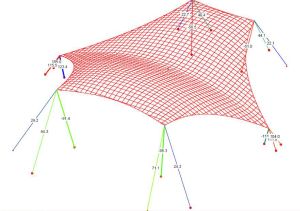

Snow load calculations

|

Wind suck calculations

|

Breaking snow load

analysis

|

|

Mast calculations

|

Wind analysis

|

Pattern generation

|

Types of fabric structures

- tension membrane;

- conical;

- beam;

- combined.

Supporting frame

Frames and poles of textile architecture can be made of steel, concrete, wood, or combined solutions, depending on the chosen design variations in the design process. Structures can be calculated with or without snow loads, depending on the purpose of the structure as well as customer’s request.

Cover

PVC acrylic or PVDF covered material, PTFE Teflon covered materials can be used for textile architecture structures, improving the aesthetic image of the structure as well as prolonging the life of a structure. Material elasticity and weight are directly dependent on construction and shall be selected after analysis of the structure.

Cables and connections

Cables and fittings are made from steel or stainless steel, connections and other parts of the structure can be produced from galvanized steel. Endings of the cables are factory-waged.

Design and realization steps

I. Design conception – Design conception can be offered by an architect or architectural company. Designs can be created either on plain paper or by using special software. From your design, the model and/or computer visualization of the project can be completed. Without sufficient previous experience in designing textile structures, it is important to contact specialists to check the form, otherwise a customer may produce an architectural design that is nearly impossible to implement.

II. Load analysis – This step is directly connected to the design conception. The architect-designed form must be checked, materials selected, estimate of the project given, and documentation of the technical project prepared. This analysis must be done by an engineer with practical experience in the design and calculation of textile structures as well.

III. Preparation of the working project – In this step, detailed working drawings for the production are prepared. These preparations are carried out be either the producer of the structure by evaluating available production equipment and production technologies used, or an engineer who completes the technical aspects in cooperation with the producer.

IV. Production – The actual production is completed by companies that meet our high quality and technology requirements, which are defined in the preceding steps.

V. Installation – Installation has to be done by certified construction companies that have experience in installation of textile structures as well as theoretical knowledge.

For more information or to request an offer, please fill out our inquiry form and we will contact you as soon as possible.

DESIGN RESULTS |